Why is My Sewing Machine Not Working???

*This post may include affiliate links, which allow me to make a small commission off your purchases. The money is earned at no additional cost to you.

Lately, many have asked, “Why is my sewing machine not working.” The following blog will help you to go thru the process of elimination to discover common reasons for sewing machine problems.

Is your needle moving up and down at all?

When a sewing machine needle is not moving at all, there are a few possibilities.

- Not oiled. Vintage machines especially need oil before every use.When a machine hand wheel won’t turn at all, get the oil out and lubricate every moving part inside.

- When the sewing machine won’t move at all, the foot control is usually the culprit. For an old metal (light/motor block) foot pedal, check out this older article from my blog. In the blog, you’ll discover how to restore an old metal foot control by replacing worn coils. Got an electronic foot pedal? Open the foot control to see if it takes carbon brushes. Worn? Replace them.

- Sewing machine belt is broken. To check this, you will need to unscrew the hand wheel and peek inside to see if the belt is in tact. For a broken belt, you will need to remove the belt and use a tape measure to find it’s circumference. The belts are measured in millimeters. Therefore, you will need to convert your measurement to millimeters. For example, the belt for my Emdeko JA21 is 350mm. Therefore, it takes the MB-350 motor belt.

Part II: Is your needle moving up and down at all?

- Do you hear the motor at all when you press down on the foot control? When you don’t hear anything from the motor at all, it can be a minor problem like an issue with the electrical wiring. Check the wires to see if there are any cuts or burs. Replace bad wiring by visiting your local hardware store for a wiring kit.

- When you don’t hear anything from the motor and it’s not the wiring, remove the motor and see if it will turn when plugged in apart from the sewing machine. No action from the motor? It needs to be replaced.

- When it’s not an issue with the motor or wiring, it’s something more serious like a bad circuit board, or even an issue with parts inside of the machine . This is something that has to be fixed by a service technician because the machine will have to be taken apart to access the problem. For circuit board problems, replacements are not always available 🙁

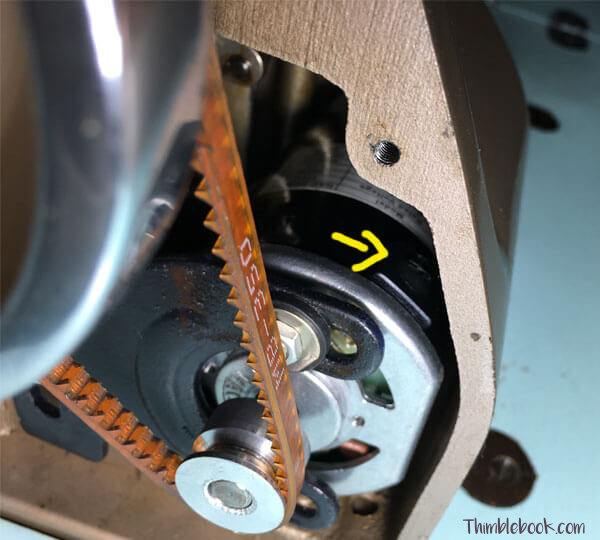

Screw port is just barely noticeable, but ever present on this aftermarket motor.

Does your sewing machine stop and go? Or, does your machine lack the power it once had?

- Carbon brushes inside of the motor are most likely worn out. The vast majority of older home sewing machine motors take carbon brushes. To see if your sewing machine motor takes a carbon brush, look for a small screw port on the side of the motor. The screw port is where the carbon brushes live. Open the port(s) and check to see if the brushes are worn. If they are wore, hit Amazon or your local hardware store for replacements.

Capacitor circled in red.

Is your sewing machine going too fast?

For sewing machines with an electronic foot control, 80% of the time there is a broken capacitor inside the foot control. To fix this problem, you will need to know how solder on a new capacitor. I understand most of you don’t know how to do this. In this case, it is more cost effective to just purchase another foot control.

When you ask “Why is my sewing machine not working,” are your stitches coming out ugly?

When is the last time your machine was cleaned?

Any lint or dirt can easily cause stitches to not come out well. Use canned air or a compressed air duster to clean lint out from underneath the needle plate. Then, use dental floss to floss the upper thread tension disks clean.

Did you read the sewing machine manual again before you threaded the machine?

You may have been using the sewing machine for years. But, one missed step in the threading processes will cause stitch quality problems.

Box of different sized sewing needles.

Did you change the sewing machine needle?

Change the needle because old needles cause missed or malformed stitches.

Are you using the right needle for the job?

The wrong size needle and wrong type needle will make a mess of your stitches.

When you asked, “ Why is my sewing machine not working,” did you think about thread tension?

Upper thread tension and lower thread tension play a tug of war with each other. When the upper or lower thread is winning, you get an ugly stitch.

- Knotted thread on the bottom of your fabric means the upper thread needs an adjustment.

- Knotted thread on top means the lower tension needs an adjustment.

Left: Bernina 1010 classic bobbin case Right: Brother SE625 modern plastic bobbin case

Are stitches not forming at all?

- Do you have thread in the bobbin case? It sounds very stupid, but I’ve fought with a machine before. After 10 minutes of trying to discover the problem, I noticed the bobbin case was empty. LOL

- Do you have the correct needle for the fabric being sewn?

- Do you see any burs, dents, or damage to your bobbin case? If so, replace the bobbin case! BTW: Always keep an extra bobbin case on hand just in case one gets broken.

- Is your thread tension adjusted proper?

- When none of these apply, there is a good chance that the timing on your machine is off. You will need to get the sewing machine serviced. Please, do not loosen any screws or try to do it yourself unless you know what you are doing!

So many problems cause us to ask “Why is my sewing machine not working.” However, the few reasons I covered are the main ones to think about. I hoped this helped. PS: Still having problems with your machine? Ask me about it in the comments section and I will try my best to help. Happy sewing everyone!

Other Helpful Articles

The Insider’s Guide to Sewing Machine Repair Part I: Electrical Cords

The Insider’s Guide to Sewing Machine Repair Part II: Foot Pedal Repair

2 Comments

Leave a response

I am the original owner of a Touch & Sew 758. No trouble in the past. For some reason, it is not working. It does almost a full wheel turn, up and down, but then starts going left to right, hits something in the bobbin compartment and breaks the needle. It also has stopped winding the bobbin. I cannot find a repair shop close to zip code 04915 and don’t know what to do.

I can’t see the machine, so it is hard for me to judge what is wrong with it. Usually, it takes a process of elimination to find the issue with a machine. Are the cams in tact? Is the cam stack worm gear in tact? Is the stitch selector gear broken? Is the needle bar screw (which determines how far or back the needle sits in relation to the needle plate) adjusted properly?