Information About Singer Touch N Sew 648 & Other Models

*This post may include affiliate links, which allow me to make a small commission off your purchases. The money is earned at no additional cost to you.

I wanted to only speak of my Singer Touch N Sew 648, but cannot do so without giving information about the 600 line as a whole. I’ve included lots of information about the line including a full parts list for those of you interested in doing restorations.

Touch N Sew 600 Series History

In the beginning was auto reel

In 1965, Singer released its first machine in the 600 series called the 600 Auto-Reel. The auto reel was like a Singer 500 with a different body style and a brand new bobbin winding system. This bobbin winding system allowed the bobbin to wind in place and was revolutionary for the industry. Early model machines had the auto winding feature set on the front exterior.

Changes to refine the design

Later, the design was refined by moving this auto-reel system from a front exterior position to underneath the slide plate. Also, the name was changed from auto reel to the catchier Touch & Sew name. Within the next couple of years, a number of different versions of Singer Touch and Sew released. These models all had same body style but different colored face plates and varying features for different price points.

Features common to all 600-626 models

- 5MM maximum stitch width

- 7inches of throat space

- Wind in place bobbin winding

- .75 amp motor

- Option for rubber feed dogs or metal ones

- Slant shank presser feet

Varying Features

Upscale models had built in decorative stitches and included a hatch for design cams, while some economy models only did a straight stitch and didn’t include a hatch for design cams at all.

The motor

Many models feature a .7AMP motor. But, there are a few labeled 1.0AMP. Inside of the motor, I don’t notice any true differences in the amount of windings. Likewise, I don’t notice any difference of performance between a .7AMP model and a 1AMP one. But then again, I’m no expert on motor amperage.

On later model motors, you cannot remove the motor without taking out a nylon set screw secured on the bottom. If you forget to remove the nylon screw, it will break. But, I’ve provided a link to a replacement screw at the end of this article.

Also, the motor brushes are very specific. You need 5.3w x 5.3L motor brushes. This brush size is hard to find. So, its often necessary to go with a 5mm or 5.5mm brush. When you go with a bigger brush, there is a great possibility you will need to sand it down a bit to fit.

Note: Any big difference in motor brush size will not allow for the motor to run! So, its very important to get this step right.

How Touch & Sew Became Touch & Throw

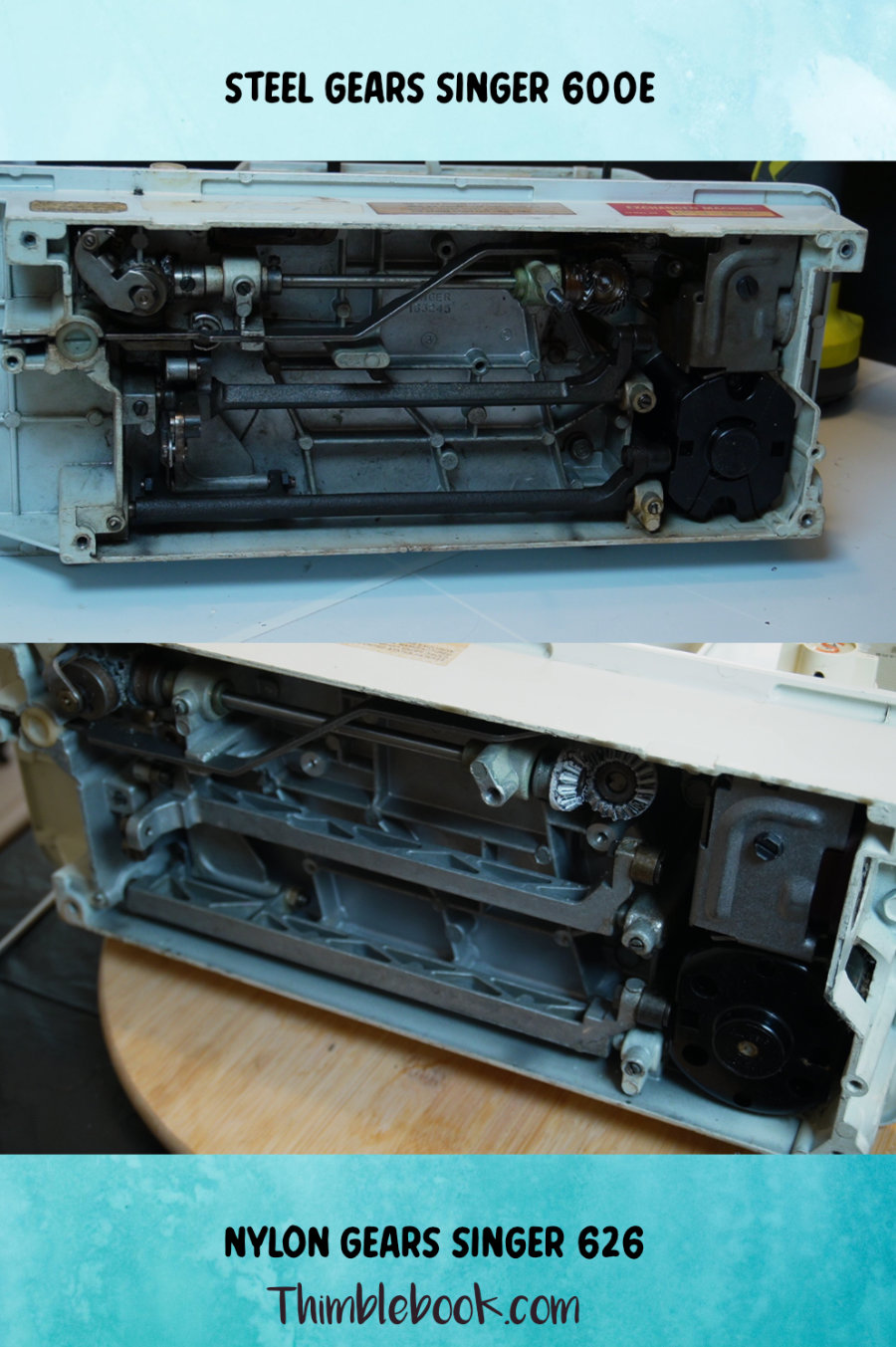

Models numbers went from 600 all the way up to 626. Then midway into production of Singer 626, they decided to cut costs by introducing nylon gears. For this reason, you have to check inside a 626 to see whether it is a version with nylon or steel gears. There’s more to say about nylon gears. But, we will speak more about them after discussing one added design feature.

The added design feature

In 1968, Singer released a golden edition 630 machine with an internal buttonhole system. In addition, 630 included a revolutionary semi automatic needle threader. As with previous machines, Singer released both luxury and economy models.

& Then there was 648

Singer 648 is part of the Touch and Sew with buttonholer family. It doesn’t have built in stitches or an automatic needle threader.

Features to Love

Design wise, Touch & Sew is toned down from the 50’s design marked by sharp angles and a daring design. Instead, you get a cream machine without a lot of pizzazz. I enjoy the lack luster because it allows me to focus on sewing projects instead of machine esthetics.

Collectors much prefer bolder design. However, I like how the face plate on 648 is removable for machine servicing. The removable plate makes servicing easier than it is with older machines, which are cast as one piece of aluminum with only a removable top and bottom.

Likewise, there is much to love about the full system of presser feet offered with the model. Earlier models have solid presser feet, while later ones offered snap on. I’m not a big fan of snap on presser feet. However, the snap on feet with 648 are primarily metal and feel sturdy.

Things to Be Indifferent About

The automatic bobbin winding system allows you to wind a bobbin without ever having to remove it from the machine. This is a wonderful feature that saves time. However, some users complain because bobbins are smaller than your average class 15 bobbin. So, you end up having to wind a bobbin more often. In the grand scheme of things, I don’t think it makes a difference for those who use 2 thread spools (one for bobbin winding and another for top stitching).

In addition to having a different bobbin winding system, many of these machines included rubber feed dogs. Rubber feed dogs disintegrate with heat or exposure to sewing machine oil. However, they offer an extra smooth surface for lightweight materials easily damaged by traditional metal ones. Personally, I prefer to use metal feed dogs. But, it all depends on what type of projects you sew.

One Feature to Hate

Quality construction was great for the consumer who used their machines for a lifetime and passed them down thru generations. But, durability led to job layoffs and financial ruin for businesses who didn’t get return customers. For this reason, Singer built in obsolescence with nylon gears. Nylon gears guaranteed consumers would need to buy another machine.

Side Note: In the 60’s, nylon gears were new to the sewing machine world. So many consumers used non-synthetic grease in their sewing machines and degraded gears faster than expected. However, my grandmother used the required synthetic grease and didn’t need new gears until the 1990’s. Once gears wore out, the machine was placed in storage and forgotten until 2024 when I acquired it.

Of course, companies didn’t market nylon geared machines as money pits. When nylon gears entered Singer, they were marketed as a way to make sewing machines run quieter and faster. Nylon gears do make sewing machines run quieter than their metal counterparts, but not by much.

Also, nylon gears were also marketed as a way to make a sewing machine lighter weight. A lighter weight sewing machine does allow it to run faster. But, this only applies when there is an equally robust motor. I weighted an all metal gears Singer Touch N Sew model 600E at 21.3LBS. Then, I weighted the Singer Touch and Sew 648 at 20.3LBS. I don’t think one single pound means much to the average person and would have much rather dealt with metal gears.

The good news is: parts are available

The overwhelming majority of parts are still available for Singer Touch and Sew. I’ve listed below all the parts and accessories I could find.

Manuals From Sewing Parts Online

Electronic foot control Singer #979314-031 | Lead cord

Standard Nylon Gear 5 Piece Replacement Kit

Standard Nylon Gear Replacements: Hook shaft gear 163329 + Lower horizontal shaft gear(left) 163997 | Lower horizontal shaft gear(right) 163996 + Bottom shaft vertical gear 174204 | Vertical shaft top gear 163328 + Upper horizontal shaft gear 163326

Beveled Nylon Gear Replacement (Supposed to glide better): Hook shaft gear 163329 + Lower horizontal shaft gear(left) 163997

Feed dogs: Metal #163713 | Rubber #163713R

Needle Plate: Zig Zag #172200 | Chainstitch Plate #21915 | Straight Stitch# 174529 | Slide Cover Singer #163477

Presser Feet: Zigzag | Straight Stitch | Buttonhole | Button | Walking foot | Blind Hem | Overcast |1/4 with guide | Free Motion | Quilting Kit

Bobbin | Auto Winder Rod (Singer #445827-451)

Nylon screw replacement for late model motor | *You’re going to need a nylon lock nut to fit it (probably have to get from hardware store. Mine came from ACE)

No Comments