The Kenmore Adapter Problem

*This post may include affiliate links, which allow me to make a small commission off your purchases. The money is earned at no additional cost to you.

If you’ve got a Kenmore super high shank sewing machine, you’ve most likely run into the Kenmore adapter problem. Today, I will discuss the problem and allow you to take it from there.

The Kenmore Adapter

Since the super high shank presser feet aren’t available, manufacturers made a super high shank to low shank adapter . This adapter allows Kenmore users to use low shank presser feet onto their sewing machines.

Alternatively, there is a secondary adapter for making a low shank machine snap on presser foot compatible. Many users opt to wear 2 adapters on their machines. One for low shank and another for snap on adapter on compatibility. Users add the snap on adapter because it is a pain to unscrew presser feet. It isn’t ideal to use multiple adapters. But, multi-adapter inconvenience is the least of our problems.

Problems with the adapter system

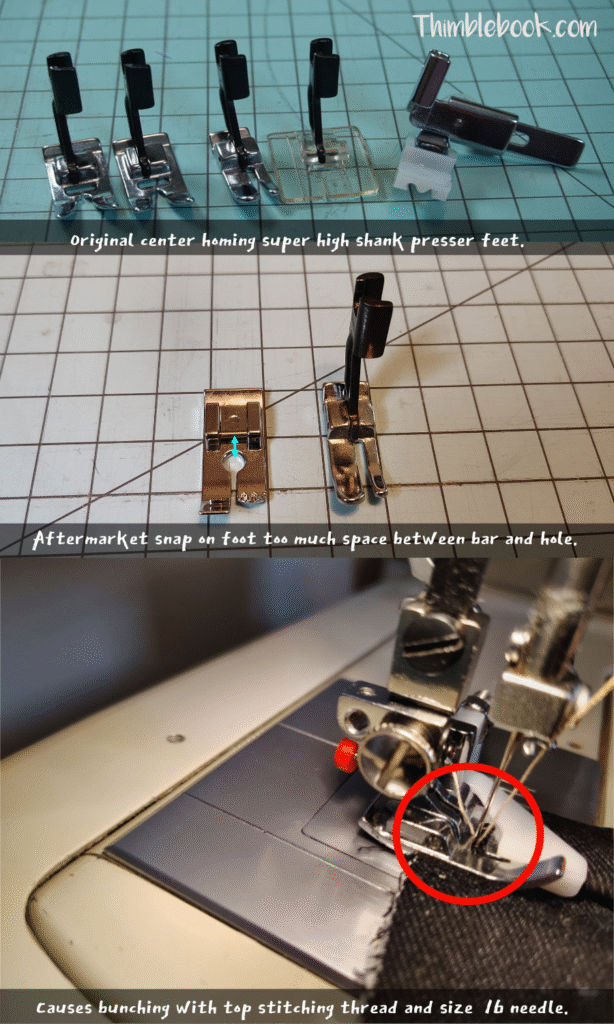

The market is filled with low shank and snap on presser feet, which all claim to be compatible with Kenmore. But, there is just one major problem! The space from bar to presser foot opening is too long! On vintage super high shank feet, the bar meets the opening (see photo). But, 90% of modern presser feet have additional metal between bar and opening (see photo). Additional metal means there is very little clearance for a sewing needle to pass thru.

When I use the modern presser feet, I can’t use a size 16 needle and top stitching thread on my jeans because it causes the thread to catch on the back of the presser foot. Just to put things into perspective, I purchased a set of 30 snap on feet. But none of the feet work without needing to worry about needle or thread size.

You thought there was just one problem with the Kenmore adapter? Ha Ha

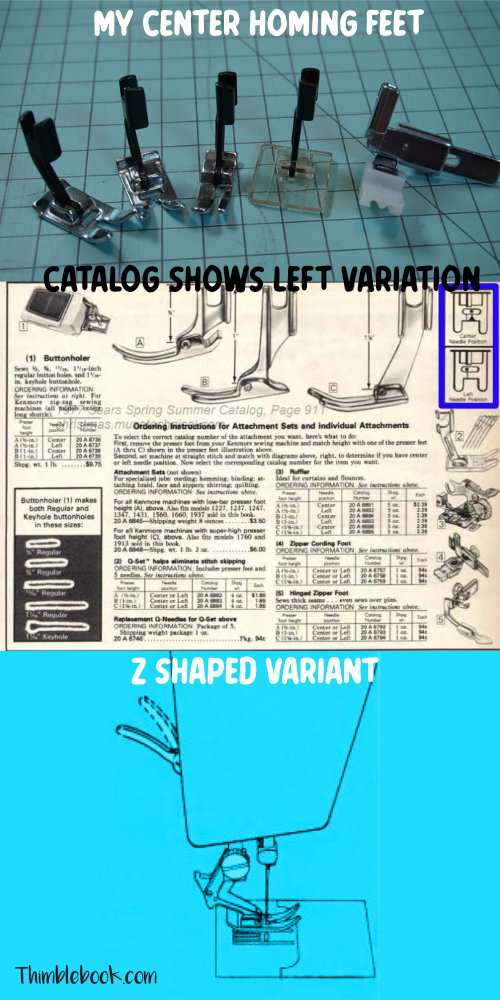

The overwhelming majority of Kenmore super high shank machines have a fixed needle position. The fixed needle position isn’t the same across models. My machine has a centered needle, but others have machines with the needle fixed left. In spite of adapter availability, the needle position issue makes it very difficult to find compatible feet.

Why doesn’t an aftermarket manufacturer make super high shank feet?

Google shows there is a very high demand for super high shank presser feet. At one time there was an aftermarket manufacturer making them. But as of the time of this blog post, the only aftermarket super high shank foot available is the zigzag foot. As a disclaimer, I would like to say this is pure speculation. But, I don’t think there would be enough profit in making super high shank presser feet.

Why not?

It wouldn’t be feasible because there are too many variations of the Kenmore super high shank foot. By the time you made all the feet and variations, there would be very little profit. Kenmore didn’t just have one set of super high shank presser feet. Instead, they made sets specifically for:

- Center needle position 158 model feet

- Left needle position 158 feet

- Z shaped super high shank (only fits 385 machines & a few later model 158 models)

The solution isn’t vintage!

Online shops often sell vintage presser feet without knowing a darn thing about sewing machines. For this reason, buyers purchase blind without knowing if feet are designed for left or center needle position. Plus, quality is an issue because Kenmore produced a number of super high shank feet in plastic. The metal feet are good and still holding up. But, plastic feet are now 50+ years old and not in the best of condition.

The solution

I don’t like to state problems without offering workable solutions. If you know of a workable solution, please do place it in the comments as it would be helpful to anyone who runs across this post.

No Comments