Why Your Sewing Machine Won’t Sew Thick Fabric

*This post may include affiliate links, which allow me to make a small commission off your purchases. The money is earned at no additional cost to you.

There are a few reasons why your sewing machine won’t sew thick fabric. Once you understand the problem, you can craft an appropriate solution and complete projects with ease.

Misconceptions

There are 3 misconceptions about what kind of sewing machines can sew thick layers.

#1 The Vintage Deception

The overwhelming majority of sewing enthusiasts think all metal vintage machines are made to sew thick materials. They believe this because vintage machines were built like tanks and made to last multiple generations. While vintage sewing machines are heavy, they aren’t made to sew thru thick layers on a regular basis.

#2 Heavy Duty Lies

Marketing experts often label sewing machines as “heavy duty” because the label makes sales. However, the term “heavy duty” has an extremely loose definition. In reality, a heavy duty sewing machine won’t sew thick fabric

Industrial Conquers All

Industrial sewing machines are made for factories. In order to understand industrial sewing machines, you must understand the work environment. In a factory, each employee works 8 to 10 hours and is assigned to complete one tasks repetitively. For example, one factory work would be assigned to sew hems while another would do buttonholes.

The industrial sewing machine is made to drive long hours without fail. Likewise, each industrial sewing machine is designed to complete one specific tasks repetitively. Therefore, a factory will have one machine design for buttonholes and another for hems. In other words, not all industrial sewing machines are made to sew heavy fabric! In fact, most of them won’t sew heavy materials at all.

Why none of the above mentioned sewing machines work for sewing heavy fabric.

There are 5 basic reasons why the average sewing machine won’t go thru thick materials.

Motor:

Powerful domestic sewing machine motors only offer 1.5AMPs of power – at most. But, machines specifically designed for upholstery or leatherwork don’t even mess with AMPS.

Feed Dogs:

Vintage sewing machines only have two feed dogs, while zigzag models have 4. The feed dogs aren’t able move thick materials through the machine. For this reason, you end up with skipped stitches or even thread knots on the bottom of your fabric.

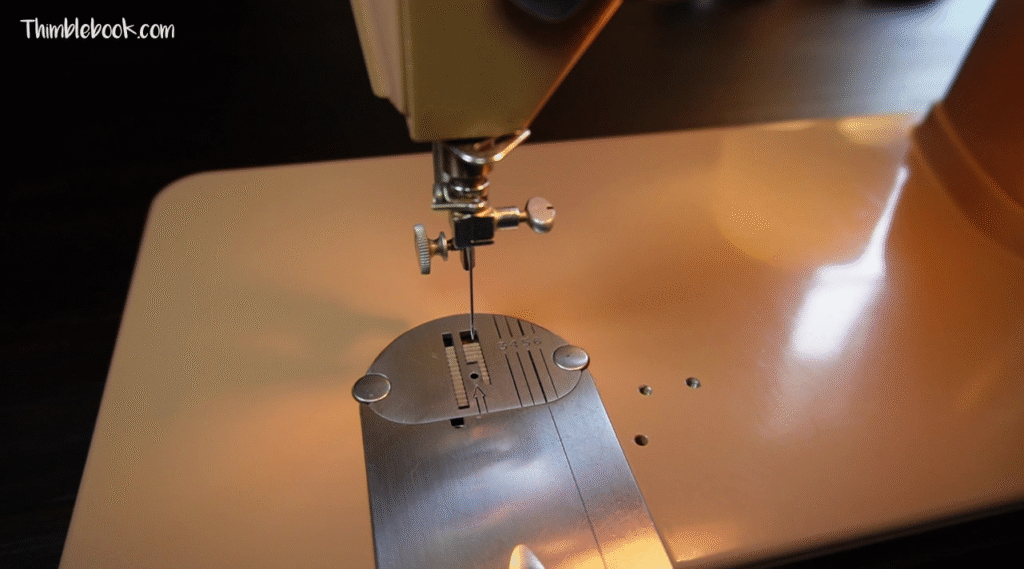

Clearance:

Domestic machines don’t offer enough clearance underneath the presser foot. This makes it impossible to even get the project into the sewing machine for sewing.

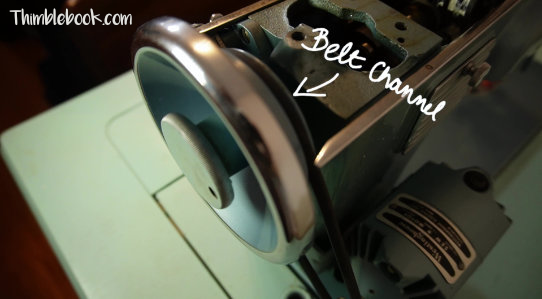

Handwheel:

90% of heavy duty sewing machines have a cheap plastic handwheel, while vintage models offer a metal one. A heavier handwheel is better because it allows the machine to have a bit of driving force behind it for going thru tough fabrics . Regardless of metal or plastic, domestic sewing machine handwheels still are not suitable for sewing heavy fabric because the motor belt channel is too small in diameter. The small diameter means you don’t have enough time to build up the momentum needed on each revolution.

Pulleys and belts:

Domestic sewing machines only have one belt from motor to handwheel. This belt transfers power from motor , to handwheel, and finally down to needle. In the transfer o, power is lost. However, some domestic machines remedy this problem by offering additional pulleys and belts to better distribute power and reduce energy loss.

Alternatively, there are direct drive domestic sewing machines with no belts at all. On direct drive machines, a series of gears transfers power from motor to needle. While added pulleys and belts reduce loss, domestic motors are still not adequate for driving thru thick materials on a regular basis.

Stitch length:

Your sewing machine won’t sew thick materials because the stitch length is wrong. The average domestic sewing machine has a maximum stitch length between 4 and 5. Small stitch lengths are not ideal for sewing thick materials because it causes bunching.

The actual solution

In order to sew thick materials on a regular basis, you need a walking foot sewing machine. A walking foot sewing machine has a built in presser foot that walks along the top of your material. When the built in walking foot is used in concert with already existing bottom feed dogs, you get better pull.

For those of you on a tight budget, you can purchase a walking foot for a domestic sewing machine. However, the store bought walking foot will further diminish the space underneath your presser foot. You can get by with a store bought presser foot on some projects. But, it doesn’t work for truly heavy duty projects where every millimeter of space underneath the presser foot truly matters.

There’s different types

You’ve got dual feed walking foot sewing machines and then you’ve got the triple feed. Triple feed walking foot sewing machines add a third layer of walking. On a triple feed, the needle walks along with the bottom feed dogs and the top walker.

What you get

On the overwhelming majority of industrial walking foot sewing machines, you automatically get:

- Heavy handwheel at the correct diameter.

- Added pulleys and belts. * Note some models require you to add an additional pulley and belt to slow the machine down and increase torque. Just remember to always check the oil pan underneath to see if there will be enough clearance for an added pulley.

- Clearance under the presser foot

- Max stitch length of at least 6MM

- A high horsepower motor made for heavy lifting

Here’s a few older models to buy used

Pfaff 1245

Pfaff 335

Singer 111

Seiko STH-8BLD

Here’s a few brand new models to consider

Non-portable with table

Portable

Other Helpful Articles

No Comments